Some types of pharmaceutical dust are harmful to human health and extremely explosive. Special attention is therefore given to ventilation and aspiration systems in chemical and pharmaceutical production facilities. These systems must fully comply with good manufacturing practices and be equipped with devices to prevent explosions and fires.

Also a significant factor in deciding whether or not to implement an explosion protection system (in addition to the safety of employees and equipment) is the safety of raw materials, which can have a very high value in this industry.

Our ATEX expertise, together with the many years of experience of our European partners, enables us to offer you explosion protection products and solutions that comply with best practice in ensuring occupational health and safety, taking into account all the particularities of the chemical and pharmaceutical industries.

Our team has successful experience of explosion protection for tanks, aspiration and pneumatic conveying systems in production facilities. You can find out more about our projects in the PROJECTS section.

Processes in the chemical and formulation industry generate dust/air mixtures, many of the chemical components are flammable and, when dispersed, explosive.

During the process, particles of bulk solids are atomised in the air and create a dust/air mixture with explosive concentrations of combustible dust.

An ignition source in the vicinity of such an explosive mixture leads to an explosion which can have a destructive effect on equipment and pose a health risk to employees.

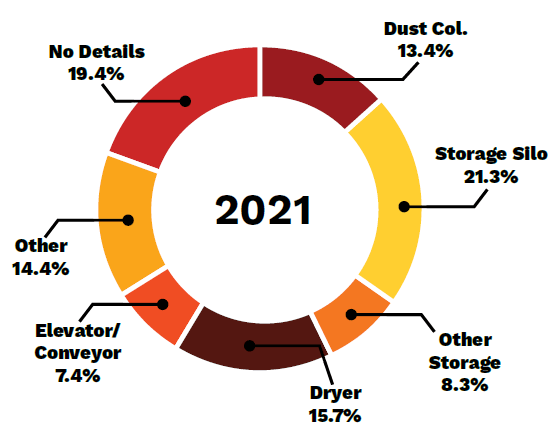

The main technological processes associated with explosive concentrations of combustible dusts:

- transport of bulk ingredients (pneumatic or mechanical systems);

- aspiration processes (cyclone separators, filtering systems, etc.);

- storage, sampling, weighing and dosing of bulk solids (silos, bins, scales, etc.)

- mechanical separation or mixing of materials and ingredients (mills, crushers, etc.).

WHAT WE OFFER

-

Conform to MS GOST, ATEX, NFPA standards

-

Prevent an explosion of dust-air mixtures

-

Reduce risks and prevent losses from dust explosions

-

Approval of the explosion protection project from the supervisory authorities

BENEFITS OF EXPLOSION PROTECTION

-

1

Improving health and safety at work, protecting the lives and health of staff

-

2

Protecting property and process equipment from destruction

-

3

Avoiding long production stoppages

-

4

Reducing the risk of damage and economic loss

Solutions for the safety of your production

Turnkey explosion protection system for chemical and pharmaceutical production facilities

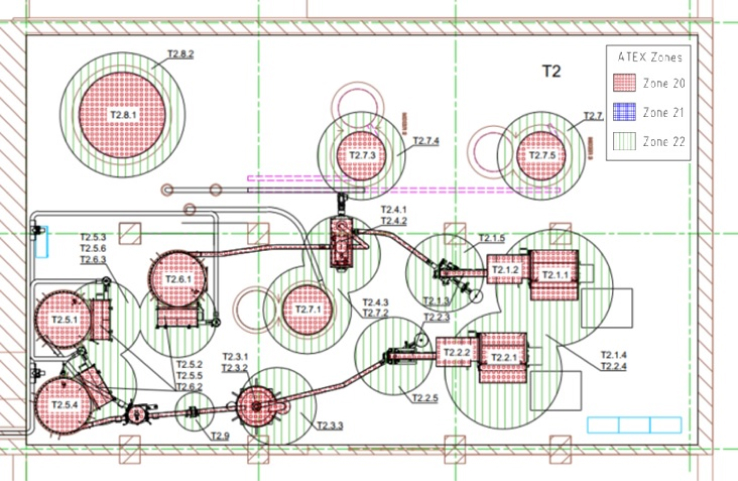

The complete explosion protection system for your plant, from analysing the explosion risk in the facility to the integration and commissioning of the explosion protection system.

Explosion protection for aspiration systems

A solution for production safety in the event of an aspiration filter explosion by reducing the explosion pressure inside the filter and cutting off the explosion from adjacent equipment.

Explosion protection for pneumatic conveying systems

Systems for production safety and explosion prevention in adjacent equipment units with HRD barrier or GATEX gate valve.

Explosion protection for tanks and silos

Explosion protection solution for hoppers, silos and other vessels by depressurisation and explosion suppression, and protection against explosion of adjacent equipment by cutting it off.

Explosion risk analysis (ATEX audit)

Expert explosion safety audit of your plant for compliance with ATEX and industry standards.

Dust explosion hazard assessment

Analysis and development of explosion protection documentation (EPD/DHA audits), dust explosion hazard analysis studies with an individual step-by-step assessment approach.

What we offer

Do you want to protect your production?

Sign up for a consultation with our experts and we'll give you all the information you need about how we can help.